Product features

Product features

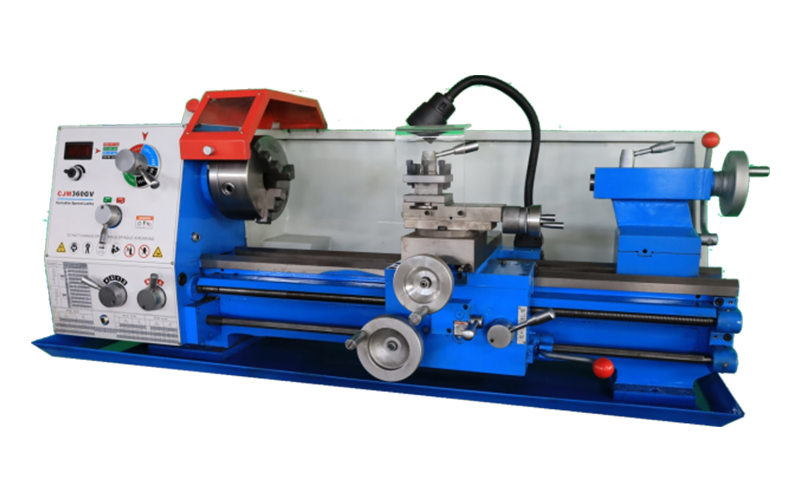

?The headstock is driven by ground gears , and the cyclic shifts changing by single handle to make the main spindle obtaining four ranges of speeds. In the selected ,range , the speed display

will show the required cutting speed by adjusting the speed knob.

The speed range is with many choics ,especially suitable for low-speed tooling.Large aperture, Spindle through hole φ52

?Feeding box with 12 steps of variable speeds ,covering common threading pitches .

?Longitudinal & cross auto feeding adopts inter-lock structure with good safety.

?High frequency hardened Two V-type widened guideway with rigidity.

?Inclined wedge toolpost carriage; Camlocked tailstock;Industrial lathe operation rod

Technical parameters | Model | |

CJM360GV/600 | CJM360GV/750 | |

Max. swing over bed | 360mm | |

Max. work-piece length | 600mm | 750mm |

Max. swing over carriage | 230mm | |

Main spindle diameter | 52mm | |

Main spindle taper | MT.6# | |

Max. cross travel of carriage | 205mm | |

Max. travel longitudinal of toolpost | 100mm | |

Metric threads range/ No | 0.25 ~7.0mm/26 | |

Imperial threads range/ No | 4 ~ 56T. P. I/ 37 | |

Module threads range/ No | 0.2 ~7M. P/27 | |

Diametrical threading range/ No | 4 ~216D. P/40 | |

Toolpost longitudinal feeding per spindle rotation | 0.049 ~ 1. 382mm/ r | |

Toolpost cross feeding per spindle rotation | 0.022 ~0.61mm/ r | |

Max. travel of tailstock sleeve | 90mm | |

Tailstock sleeve taper | MT.3# | |

Spindle speed steps | Four shifts + Speed adjustment | |

Main Spindle speed scope | 60 ~ 1600 rpm | |

Main motor power | 1. 5 kw | |

Net weights/Gross weights | 370/420kg | 390/440kg |

Overall dimensions( L*W* H) | 140×70×64cm | 152×70×64cm |

Packing dimensions (L*W* H) | 150×76×77cm | 163×76×77cm |

Stamdard accessories | Optional accessories | ||

3 -jaw chuck | Φ200 | Chip tray | Machine Base |

Belt | A type 813 | Steady rest | Follow rest |

Dead centers | MT.3#,6# | 4 -jaw chuck Φ200 | Flange plateΦ200 |

Chuck spanner | 1 piece | Face Plate Φ250 | Thread dial indicator |

Allen wrench | 4#,5#,6# | Special optional change gears(6) | Live center |

Stud dead | 12 - 14; 17 - 19 | Coolant | Work light |

Changing gears | 35T、36T、44T | Digital readout | Optional motor 2.2KW |

MN gears | 2 piece | ||

Product features

?The headstock is driven by ground gears , and the cyclic shifts changing by single handle to make the main spindle obtaining

four ranges of speeds. In the selected ,range , the speed display will show the required cutting speed by adjusting the speed knob.

The speed range is with many choics ,especially suitable for low-speed tooling.Large aperture, Spindle through hole φ52

?Feeding box with 12 steps of variable speeds ,covering common threading pitches .

?Longitudinal & cross auto feeding adopts inter-lock structure with good safety.

?High frequency hardened Two V-type widened guideway with rigidity.

?Inclined wedge toolpost carriage; Camlocked tailstock;Industrial lathe operation rod

Kind Tips:The products will be improved and updated continously. The changes shall not be noticed additionally. Due to the di?erent con?guration requirements , the machines pictures and physical objects may be di?erent , and the physical machines prevail.

Copyright 2024 Copyright Huangshan Yongfeng Mechanical and Electrical Manufacturing Co., Ltd

technical support:Smart City